As in cars, particulate filters are an important component in combined heat and power plants – with the same function. Exhaust gas particulate filters in combined heat and power plants are permanently exposed to enormous pollutant loads. This is even much higher than in passenger cars. For this reason, the reliability of exhaust gas particulate filters is more important than ever.

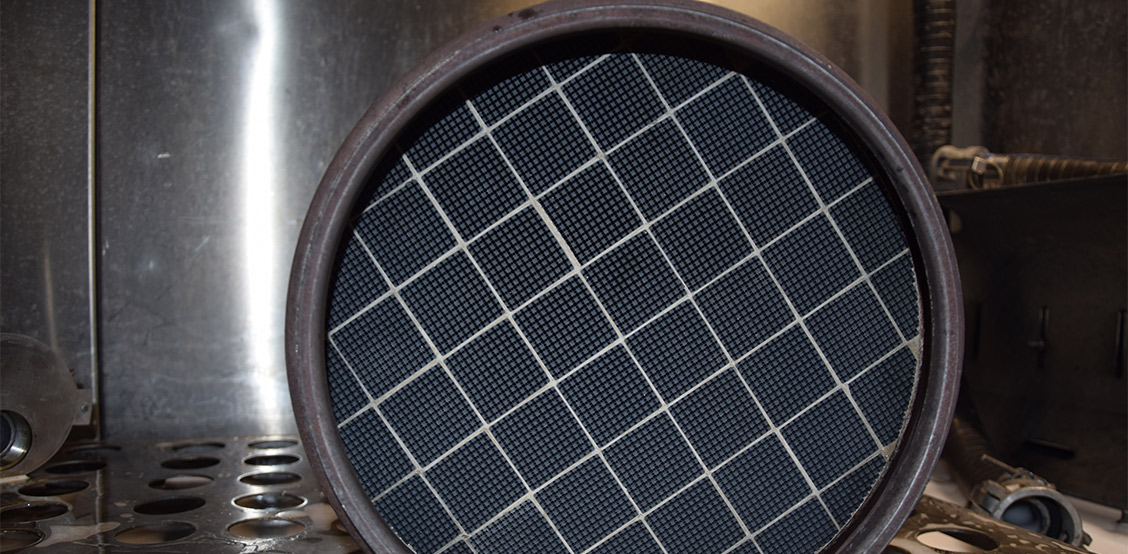

The emissions generated during heat generation must be efficiently filtered out or reduced by effective filter technologies. Thus, exhaust particulate filters made of sintered metals (sintered metal filters) are mostly used for combined heat and power plants. Due to the extremely high pollutant load, professional cleaning becomes necessary after about 1,000 to 3,000 operating hours. Only by cleaning the exhaust gas particulate filters can ash residues, soot as well as oil carbon be removed and the long-term safe, low-pollution operation of the combined heat and power units be guaranteed. Likewise, the soot particle filters of the rarely used emergency power generators must be cleaned regularly.

Why? Due to their infrequent and usually only brief use in partial load operation (or emergency), the temperature required for regeneration is usually not reached. A similar problem is already known from diesel particulate filters during predominantly short trips. This also results in a similar problem with the exhaust particulate filter in combined heat and power plants: the filter, which does not regenerate itself, becomes increasingly sooty over time, with the efficiency of the filtration suffering. Eventually, filter cleaning must provide a remedy.

For this cleaning of the exhaust particulate filters of your combined heat and power plants, you can rely on our comprehensive expertise. Feel free to contact us – we look forward to receiving your order.