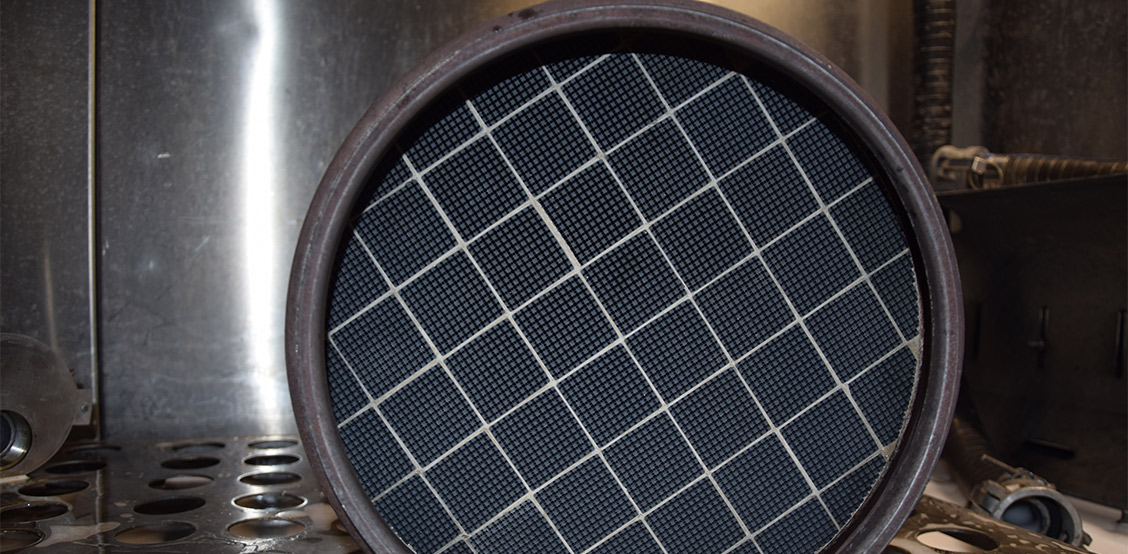

Save costs with professional particulate filter cleaning.

The cost of cleaning your filter is significantly less than the cost of a new particulate filter. Since soot filters require different amounts of effort to clean depending on their structure, size and weight, we will be happy to prepare a favorable cleaning offer for you.